Wondering what to get that special Architect in your life this holiday season? Or maybe you want to treat yourself to something that will help your architectural workflow? This holiday gift guide will help you choose a killer gift for any architect or designer. (Affiliate disclosure: Many of the links in this guide are affiliate links, so I’ll earn a …

How to Print Full Scale 1:1 in SketchUp

Full scale printing from SketchUp is useful for creating templates or stencils for cutting something on a bandsaw or scrollsaw. But if you’ve tried this in the past, you may have been frustrated at the number of blank pages that get printed, or maybe the printout splits up the model across 4 pages, when it could’ve easily fit onto one …

How to make raised panel doors in SketchUp

In this walk-through video, I show you how to make raised panel doors from scratch, and show you several tips along the way. In this video, I talk about the following: How to use Solid tools to trim components against each other How to use Intersect Faces to trim components (if you are using SketchUp Free) How to soften/smooth edges …

Introduction to the Cricut Maker and paper packaging design in SketchUp

SketchUp can be used for so many things, including paper product packaging. I recently bought a Cricut Maker, which is a paper/vinyl cutting machine, and used SketchUp to design the product packaging for some jewelry I designed. This video is an overview of the workflow, and an introduction to the Cricut Maker and what it’s capable of. In the next …

Design Considerations for 3D printing

When creating a model for 3D printing, there are several things you must keep in mind in order to be able to print successfully, especially when using a desktop printer. This article highlights some of the things to look out for. As in any type of manufacturing, there are certain limitations to the materials and manufacturing processes that dictate how …

8 Tips for 3D Printing with Sketchup

I am new to the world of 3D printing. So in this guest article, you’ll hear from expert 3D printer/designer Marcus Ritland from Denali 3D Design. He shares some tips to help you create amazing 3D printed models by designing them in Sketchup.

3D Printing

3D printing is awesome – we can all agree on that. You send a 3D computer model to a machine and out comes a finished part, ready to use as an end product or as a prototype before mass manufacturing. With the rise of personal 3D printers like the Makerbot Replicator 2, and 3D print services like Shapeways and Ponoko, nearly everyone has access to this technology.

But how does one get started making awesome models for 3D printing? Its one thing to make a model look good on the screen, but quite another to make a model that looks good and actually works in real life. The process of modeling for 3D printing is much the same as 3D modeling anything else, but with a few specific requirements. Here are some common problems that I see beginners struggling with and how to address them.

Tips for modeling in Sketchup

- Make your model “Solid” in Sketchup to be 3D Printable

Models must be “Solid” to be 3D printable. This is by far the most common problem beginners have when modeling for 3D printing. Here are some examples of Solid Sketchup models.

Solid, sometimes called “watertight” or “manifold” simply means the model is a complete enclosure. If you were to fill it with water, none would drain out, and the model must not have any extra lines or faces. If you make your object into a group or component, Sketchup will indicate when its solid in the Entity Info dialog box (Window > Entity Info).

Another way to define solid: Every edge in your model must be bordered by exactly two faces. If an edge has less than two faces bordering it, there is an adjacent hole, and if there are more than two faces touching an edge, there is an extra face that needs to be deleted.

The most common errors (and the corresponding solutions) are:

- Stray edges (just delete them)

- Holes (trace an edge to fill them)

- Internal faces (delete them)

Sketchup Tutorial – Create a Custom Bracket for 3D Printing

After coming back from the Maker Faire in NY, one thing that really surprised me was how popular 3D printing is becoming. These days, you can purchase a 3D printer for under a thousand dollars and actually print out a real object from your digital model. I’ve been learning a little bit about 3D printing at the AS220 labs, but I have yet to purchase my own 3D printer. Regardless, I wanted to show you how easy it is to use Sketchup to create a simple bracket that you can print out on a 3D printer.

Rapid Desktop Prototyping

The man in charge of connecting everybody with Wifi at the faire had a problem. He was looking to mount a piece of hardware to a round pole and looked to the Sketchup guys to come up with a solution. They were able to model something quickly in Sketchup, and print it out for him so he could mount the gear to the pole. The first prototype actually snapped during a stress test, so they just made some modifications to the design and printed out another one. How cool is that?

Creating a simple bracket in Sketchup is easy. In this tutorial, we’ll model a base plate with two arms. Now, unfortunately, I don’t have a 3D printer so I won’t be printing this out. I know, that’s lame. But you can use the same concepts in the design of this bracket to make any custom bracket for your needs.

Sketchup Tutorial – Custom Bracket

-

Draw the Base

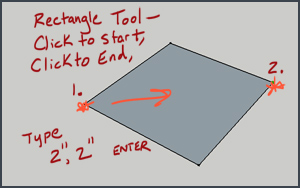

Starting with the Rectangle Tool

(R), Click once to start the rectangle, then move the mouse out and click again to finish the rectangle. To specify a precise dimension, type in

2",2"then pressENTER.Remember, you can also type in your dimensions right after your first click when you start the rectangle. It’s your choice. I like to do it after because sometimes I’ll accidentally move my mouse as I’m typing in a number and it will clear whatever I just typed in.

-

Extrude the Base

Using the Push/Pull Tool

(P), extrude the rectangle into a 3D object. Click once on the surface of the rectangle to start, then pull up. Click again to finish. Type in

1/4"thenENTERto specify the height at 1/4″.

What is 3D Printing?

Since getting into 3D modeling, I have always been fascinated with the idea of being able to create real-life objects from my digital models. I haven’t had a chance to try it out, but I recently attended a local 3D printing meeting at AS220 Labs, in Providence, RI. It was my first time ever seeing a 3D printer in real life, and I learned so much in one night I thought I’d share my experience.

The Local “Hackerspace”

When I walked in to the AS220 Labs, I could tell I was in the right place. I saw a miniature laser cut wooden trebuchet sitting on a table, loaded with mini tennis balls. There was a shiny new shop bot in the back of the space, getting ready to be set up. And there was the crowd of people, circled around a table, watching some kind of contraption whizzing away.

It was a 3D printer. The first 3D printer I’ve ever seen in person. And it was printing away at multiple copies of “mustache rings” (More on that later).

As people scooted aside to invite me into the circle, I watched in amazement as this little machine was “printing” out a 3D object. It’s really quite mesmerizing to watch it in action.

I found out about the 3D printer meeting organized by Matt Stultz from 3DPPVD on the Make website. It’s a blog/magazine that’s all about making things. It’s a really great resource for anyone who is into personal fabrication, DIY, electronics, etc. They also host the Maker Faire, which is an event that encourages the creativity within everyone to make things. There are a number of “mini” Maker Faires all over the world so you’re likely to find one near you.

Solar-Powered 3D printer

Imagine being lost in a desert, hot and exhausted with the sun’s intense heat beating down on you. You find water, alas, but if only you had a nice cup to drink out of… Well, if you happen to bump into Markus Kayser, perhaps he will make a cup for you using his solar-powered 3D printer!

3D Printing via Sun & Sand

After successful creating his SunCutter, a solar powered “laser” cutting machine that is capable of burning designs through thin plywood, Markus set his sights on creating things using the sun and sand. The SolarSinter is a self-sufficient 3D printing machine that uses sand as a medium, and the sun to provide heat and electricity to melt the sand into 3D glass objects.

Sketchup 3D Printing

When Google introduced Sketchup to the world, I thought it was so cool how I was able to create anything I could dream up. Well, at least in the digital world. I never thought about actually having my Sketchup models fabricated. Well, not only is it possible, it’s affordable! There are many companies out there that specialize in a variety …

Starting with the Rectangle Tool

Starting with the Rectangle Tool Using the Push/Pull Tool

Using the Push/Pull Tool